Walking down the street, have you noticed the increasing number of electric vehicles (EVs) gliding by silently? As more people switch to modern electric rides, a common question arises: “Since EVs have no engine and don’t need oil changes, do they still need ‘oil’ at all? Is the traditional lubricant industry becoming obsolete?”

The answer is: “Absolutely not!”

In fact, the lubricant industry is not disappearing; it is undergoing an unprecedented technological revolution. While traditional engine oil has taken a back seat, it has been replaced by a group of high-tech, high-precision specialized liquids—e-Fluids. These are the “blood” of the electric vehicle, ensuring the heart of the power system beats safely and efficiently.

Today, we reveal the three surprising secrets behind the “e-Fluids” hidden inside every EV.

Secret #1: When Coolant Must Avoid Conductivity—The Life-Saving “Insulation” Mission

When we think of coolant, we usually picture the radiator fluid in an internal combustion engine (ICE) vehicle, designed to cool a scorching engine. In an EV, however, the target is entirely different. Instead of a mechanical engine, the coolant services high-voltage batteries, inverters, and onboard chargers.

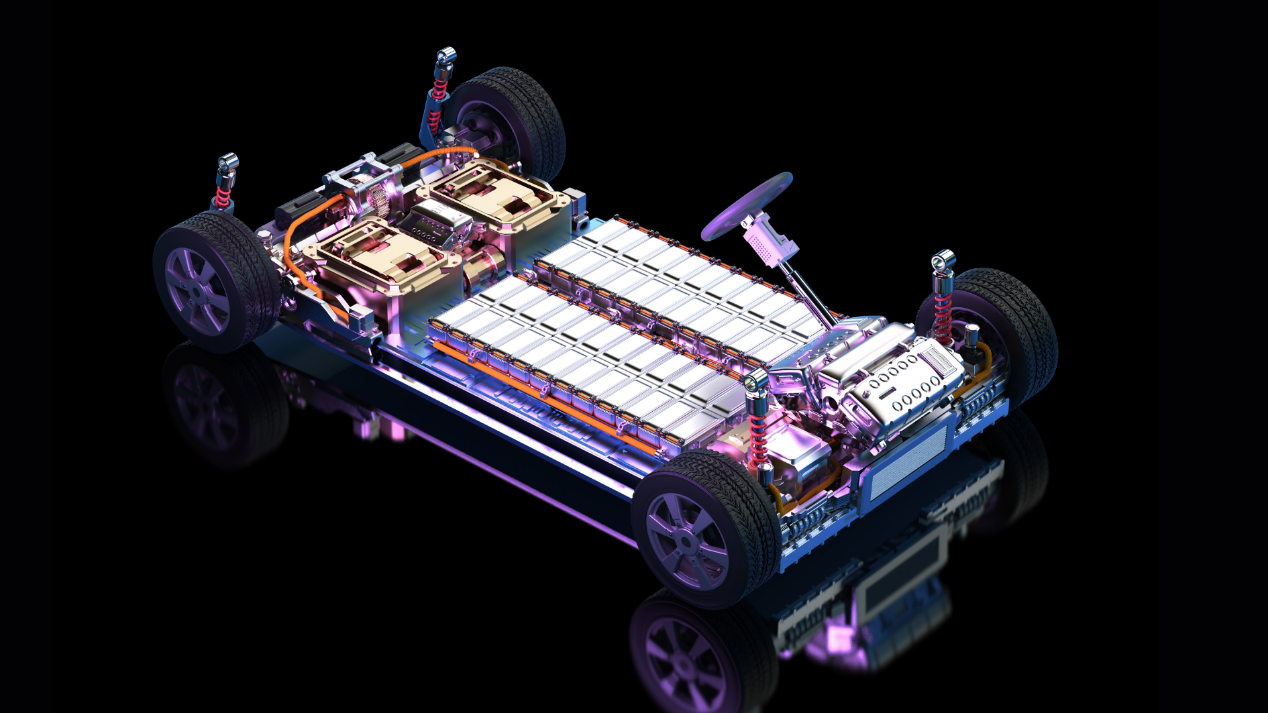

The Core of the EV: A transparent view of the EV chassis reveals the high-voltage battery pack and drive units arranged closely. These precision components require high-insulation e-Coolants for thermal management to prevent overheating and ensure driving safety.

This grants e-Coolant a grueling “dual mission.”

First and foremost is electrical insulation. Imagine if the fluid cooling a high-voltage battery was conductive. Any leak could cause a massive short circuit, damaging expensive electronic components or even leading to severe safety hazards. Therefore, professional e-Coolants must maintain a Volume Resistivity higher than 100 MΩ·cm to ensure safety within 400V to 800V high-voltage systems.

But insulation isn’t enough. e-Coolant must also be more efficient at “wicking away heat” than traditional fluids to ensure battery longevity and range. Technical standards require a Specific Heat Capacity 5% to 15% higher than traditional products.

This creates a formidable technical challenge: How can a fluid act as both a top-tier electrical insulator and a high-efficiency thermal conductor? This completely disrupts our understanding of traditional “radiator water,” elevating coolant performance from simple thermal management to the level of life-critical electrical safety.

Secret #2: Challenging the 20,000 RPM Limit! Beyond Lubrication—Protecting Copper Coils

Guardian of the Copper Coils: EV motors are filled with these copper windings. Jet-Super e-Axle Fluids utilize a specialized anti-corrosion formula (ASTM D130 1a rating) to prevent the oil from eroding the insulation layer of the copper wires, avoiding motor burnout.

While EVs lack traditional multi-speed transmissions, they still require reduction gears to regulate motor power. The e-Axle Fluids responsible for lubricating these gears face environments far harsher than traditional transmission fluids, meeting a “triple threat” of mechanical, chemical, and physical challenges.

- The First Challenge: High-Speed Shear Force. Electric motors can easily reach speeds of 15,000 or even 20,000 RPM! Such high speeds exert massive mechanical shear stress on the oil. To ensure the oil film isn’t “ruptured” at high speeds, the stability of High-Temperature High-Shear (HTHS) viscosity is critical, with a required change rate of less than 10% after rigorous testing.

- The Second Challenge: Chemical Compatibility. These fluids come into direct contact with the copper coils inside the motor. Certain additives in traditional lubricants can corrode the insulating varnish on these wires. Therefore, e-Axle Fluids must use specialized copper-compatible formulas, achieving the highest 1a rating in the ASTM D130 copper strip corrosion test.

- The Third Challenge: Air Release Performance. High-speed rotation churns air into the oil, creating bubbles. If these bubbles don’t dissipate quickly, it leads to lubrication failure and poor heat dissipation. Top-tier e-Axle Fluids require an air release time of less than 5 minutes.

This means EV transmission oil is no longer just a mechanical lubricant; it is an “electronic-grade chemical” designed to function perfectly under extreme pressure.

Secret #3: The Battlefield Has Shifted! From “Internal Combustion Chemistry” to “High-Voltage Electrochemistry”

The rise of e-Fluids represents a fundamental shift in the industry.

The core challenge for traditional engine oil is managing chemical byproducts—like carbon, sulfur, and nitrogen oxides—to prevent sludge and carbon deposits. Its battlefield is “Internal Combustion Chemistry.”

In contrast, the core challenge for e-Fluids is maintaining chemical stability and insulation under prolonged, high-intensity electrical fields. Researchers must ensure that base oils and additives do not contain substances that produce free radicals or active ions under high voltage. This is a brand-new frontier: the battlefield has moved to “High-Voltage Electrochemistry.”

Shifting from ICE Chemistry to Electrochemistry: Every drop of Jet-Super e-Fluids undergoes strict laboratory testing to ensure chemical stability in high-voltage environments, eliminating free radicals and providing long-term insulation protection.

Summary:

The era of electric vehicles is not the end of lubricants; it is the dawn of a new era shifting from “internal combustion lubrication” to “electrified thermal management and drivetrain protection.” e-Fluids are the invisible keys to high efficiency, long range, and safety in future EVs.

Conclusion: The Unsung Heroes Driving the Future

So, are EVs truly “oil-free”? Clearly, the answer is no. The lubricant industry hasn’t disappeared; it has undergone a profound technological upgrade to enter a field with higher standards and greater technical complexity.

From insulating coolants to transmission fluids that withstand 20,000 RPM while protecting copper coils, these e-Fluids are the “invisible guardians” ensuring every EV runs safely and efficiently.

While we enjoy the quiet power of an electric car, let’s not forget the sophisticated “e-Fluids” working behind the scenes to make it all possible.